products

Flaw Detectors

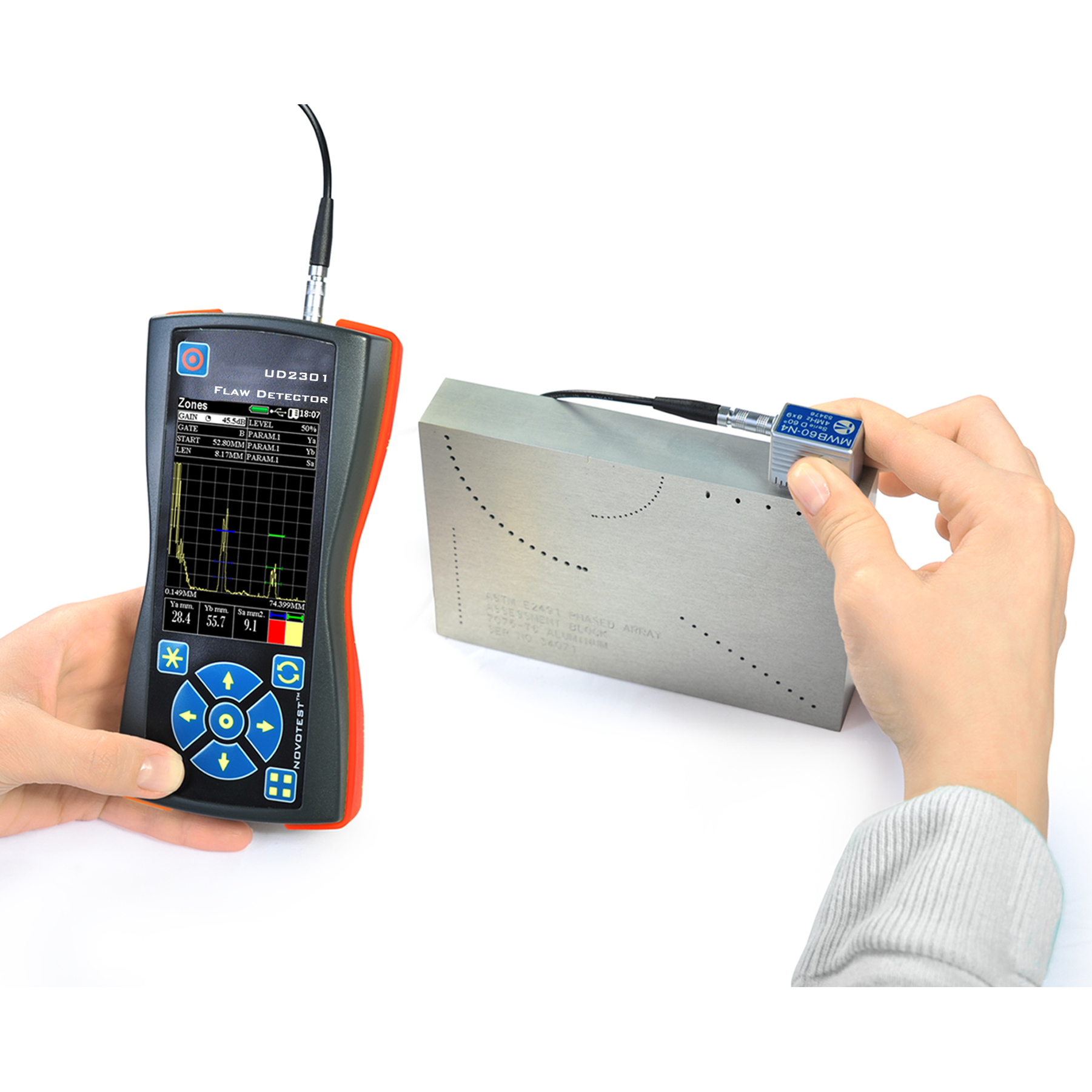

Ultrasonic Flaw Detector NOVOTEST UD2301

Ultrasonic flaw detector UD2301 is designed for nondestructive testing of metals, plastics, glass, composite materials, weld inspection and measurement thickness of the various products and structures.

Flaw detector allows user to detect various defects such as discontinuities, cracks and heterogeneity of materials in semi-finished products and welded joints, to measure the depth and coordinates of defects, the thickness of products, the speed of propagation and attenuation of ultrasonic vibrations (UT) in the material.

Ultrasonic Flaw detector has an optimal size to perform measurements in tight spaces. Device equipped with a clear color display with a high resolution of 480 * 320 pixels, which significantly improves the usability of the device.

Advantages

Display of the device can be operated in any orientation. There are 4 options for display orietation. This allows to customize instrument for both left handed and right handed users. Instrument can be operated in both portrait and landscape orientations.

Ultrasonic flaw detector UD2301 is designed to:

- test the quality of welds and base metal of products;

- detect corrosion, cracks, delaminations and other internal defects;

- determine coordinates and parameter estimation of defects such as discontinuity, cracks and uniformity of material in products from metal, plastic, composites and other materials;

- measure the thickness of products.

Flaw detector is equipped with 3 standard type AA rechargeable batteries. The device can also operate from simple batteries the same type. Using the batteries of standard type allows autonomous operation of the device in almost any conditions. User can charge batteries or use spare batteries.

Flaw detector allows user to solve a wide range of tasks starting from the thickness measurement of thin products ending with the large-sized casting flaw detection.

Ultrasonic flaw detector UD2301 has a sealed housing with rubber protective strips which is ideal for use in workshop and field conditions with high humidity, dust, etc. Device has frost-resistant display that allows you to use the device at very low temperatures.

Specifications

Operating frequency range from 1 to 10,0 MHz

Range of measured time intervals (duration of scanning) from 6 to 1000 µs

Velocity range 1000 – 9999 m / s

Error of measurement of time intervals not exceed ± 0,025 µs

Maximum permissible error of measurement of the amplitudes of the signals at the receiver input in the range from 0 to 110 dB not exceed ± 0,5 dB

Testing gain range 125 dB

Averaging over the quantity of starts from 1 to 16

Range of variation of temporal sensitivity adjustment (TVG) 40 dB

Number of control points TVG 15

Duration of the excitation pulse to the load from 0,0 to 0,5 µs

Amplitude of the excitation pulse to the 50 Ohm load, not less 100, 200, 300

Operating frequency range of the receiver on the level -3 dB from 1 to 10 MHz

Deviation of the amplitudes of input signals in the range from 10 to 100% of the screen height not more than 1 dB

Scanning from 1 to 1000 µs

Delay of scanning from 0 to 2000 µs

Range of measurement of time intervals from 0 to 1000 µs

Setting a delay in the prism of the probe from 0 to 15 µs

Automatic signaling of defects (AFS) dual-gate

Setting range of AFS gates from 0 to 2000 µs

Adjusting thresholds of AFS gates from 0 to 100 % of screen height

Detection of signals positive half-wave, radio mode

Dimensions (W*H*L) 80*162*38 mm

Weight, not more 250 g (without batteries)

Mean time between failures not less than – 3000 hours

Available options

Different colors of rubber bumper protected case

Couplant

Calibration blocks:

– Calibration block V1

– Calibration block V2

Standard package

Ultrasonic flaw detector

UT-probes – 2 pcs

Cable Lemo-Lemo – 1 pc

AA batteries – 3 pcs

Charger

USB cable for PC connection

Operating manual

Case

Media